Aircraft Assembly & Structural Repair Solutions

for Aviation Maintenance, Repair, and Overhaul

Increase Fleet Readiness

Reduce Corrosion Repair costs

Validate Life Extension Credits

Solving Challenges in the Aviation Maintenance, Repair, and Overhaul (MRO) Industry

The aerospace Maintenance, Repair, and Overhaul (MRO) industry faces ongoing challenges, including increasing aircraft downtime, managing corrosion repair costs, and ensuring the accuracy of repair validation. These issues can lead to reduced fleet readiness and higher maintenance costs. The PartWorks RepĀR™ Augmented Reality (AR) solutions for airframe hole repair, fastener installation, and cold expansion validation tackle these problems by reducing repair time, improving data accuracy, and ensuring validated life extension of critical aircraft components. This is essential to ensuring efficient operations, reducing costs, and maintaining aircraft availability in both military and commercial aviation.

Explore the possibilities

Learn about Cold Expansion

Increase Fleet Readiness

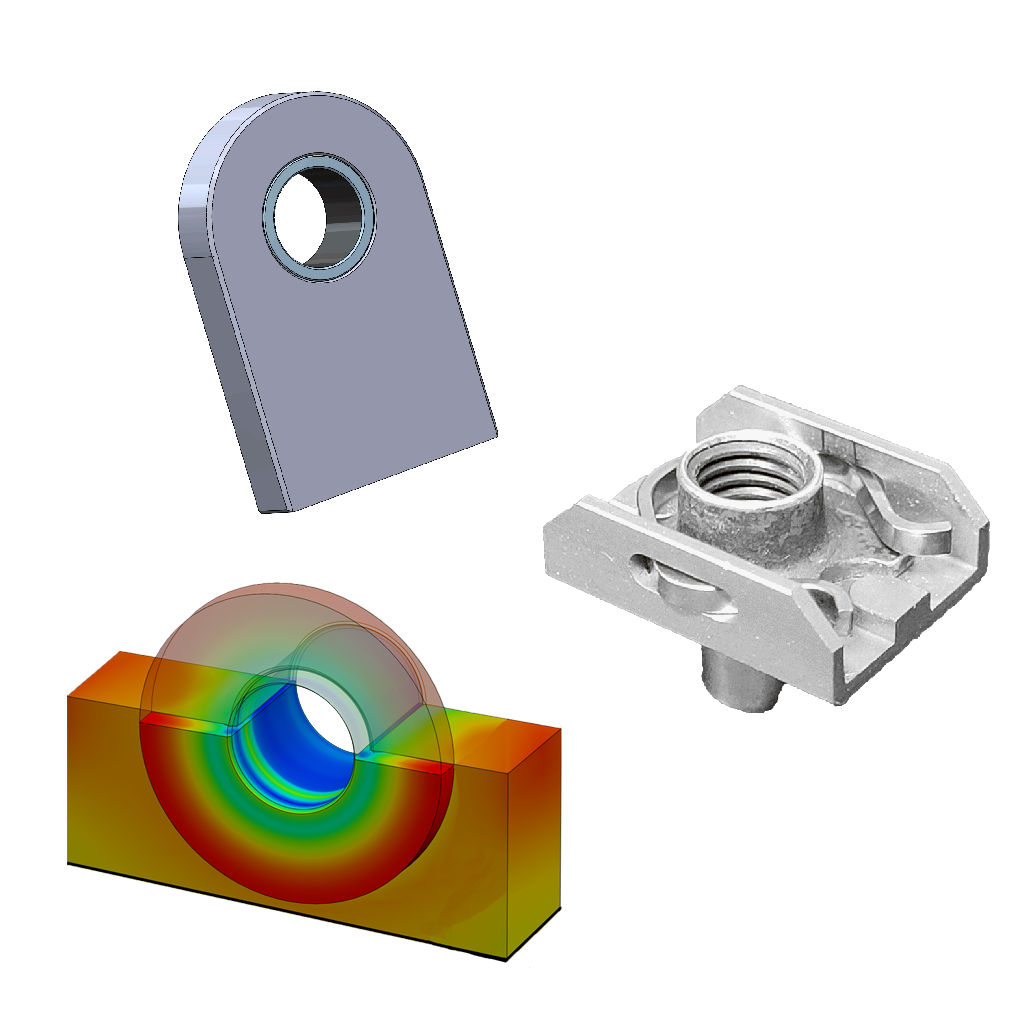

Fleet readiness improves significantly with PartWorks’ patent-pending solutions, including ultra thin-walled bushings and bushed rivetless nutplates. These innovations dramatically reduce corrosion hole repair time and extend the fatigue life of components, delivering up to 10x life extension, which results in increased aircraft availability.

Reduce Corrosion Repair Costs and MRO Labor Costs

Fleets experience a transformative reduction in corrosion repair costs with PartWorks’ patented installation and process validation tools. By standardizing the labor involved in aircraft repair and providing tools that inform operators when a task has been correctly completed, PartWorks RepĀR helps reduce MRO labor costs while ensuring compliance.

Validate Life Extension Credit

The PartWorks RepĀR cold expansion validation system allows fleets to validate repairs in situ. Using a combination of digital image correlation (DIC) and other advanced technologies, our system supports the validation of cold expansion processes, ensuring that life extension credit is justified and documented.